|

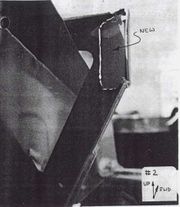

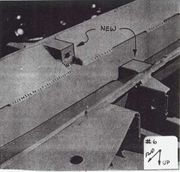

A 12 gauge (2.66mm) panel welded to the underside of the front

cross-member, where the jack is usually and erroneously - placed when lifting

the front of the car. A tow loop may be welded to this plate. Many Elans have had their bump steer

readjusted by moronic towing attempts from the big holes in the rack

|

|

|

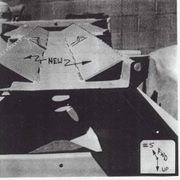

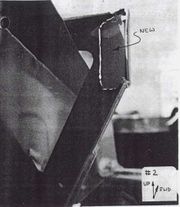

A new, thicker 14 (1.9mm) gauge, inboard sway bar support tab added

on each side (left picture not drilled through yet).

|

|

|

|

A 16 gauge (1.9mm) reinforcing

pad spot welded to the aft side each engine mount, to

alleviate the cracking that frequently occurs here (left picture not drilled

through yet). Later models may have come from the factory with these.

|

|

|

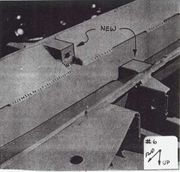

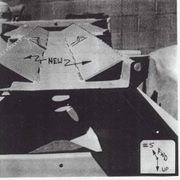

14 gauge (1.9mm) reinforcing strips

welded in along the whole length of the underside of the central frame, on

both sides. The openings should be closed off in the

front to prevent scooping up dirt and road debris. Note the differential

torque rod mounting blocks, described in the next photo. This modification

may require re-routing of the rigid brake line through the tunnel due to the

position of the exhaust pipe. It is probably a good idea to drill some holes

and spray a rust retardant in the closed areas.

|

|

The holes (early models) or stock

welded-on differential torque rod studs (later models) replaced with drilled

steel square stock through which longer standard bolts are installed to

secure the torque rods

|

|

14 gauge (1.9mm) reinforcement pads

welded, on each side, on the bottom side of the top flange of the arms

forming the engine bay, just forward of the curved cross-member. This area

often develops distortion and cracks

|

|

|

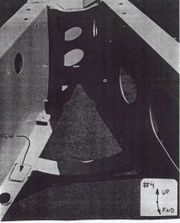

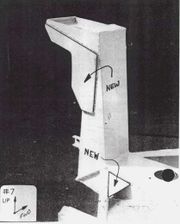

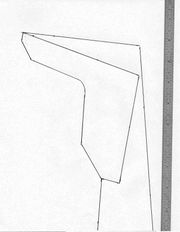

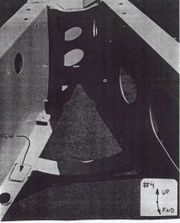

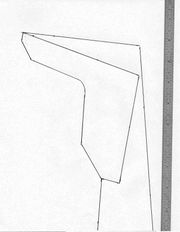

Reinforcement of the rear strut towers

with a welded-on 14 gauge (1.9mm) plate on the aft side. Template for

strengthening the rearmost two towers by welding in 14 gauge triangular

gussets.

|

|

|

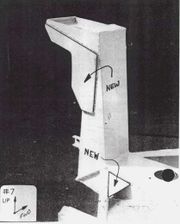

These "wings" are three point

seat belt mounts, welded directly to the chassis. This was less expensive

than having original style brackets fabricated

|

|

Replacement of the cross-member under the

engine with one that is removable. The cross-member is a hollow rectangular

tube with the ends filled with solid stock and drilled. Note the 14 gauge (1.9mm)

reinforcing plates on the top side of the cross member anchoring points

|