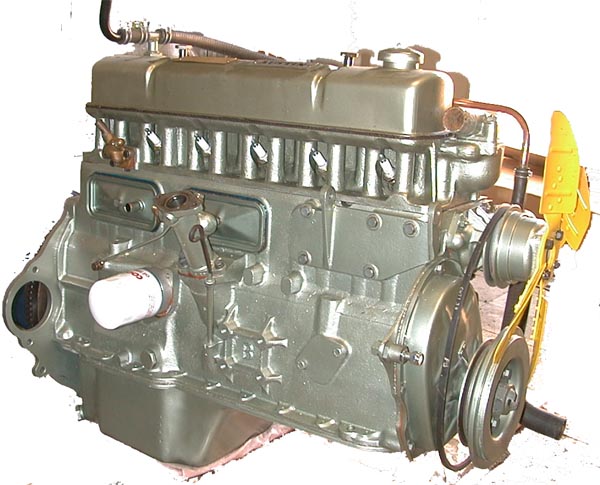

This is the monster: 90 kg just for the bare block! When you consider that a modern-day Formula 1 engine weights 120 kg COMPLETE and produces in the range of 750 HP, it forces you to put things in perspective

The rebuild of this engine was somewhat indirect. Before the purchase I was careful to assess the state of the engine. Noises, vibration, oil in water, oil pressure etc… Well, I did not realize that the oil takes quite a bit more time than the water to warm up in the engine, and having the water temperature at 80C (180F) does mean your oil hot yet.

Thinking the engine was OK, in a 1st phase I cosmetically revamped it plus new gaskets and seals where accessible. When I first put the restored car on the road the verdict was: 32 PSI when (completely) hot. Although racers told me that as long as its over 25 it’s OK and other owners are quite happy with 30, I felt kind of miserable to have such a nice car with such modest oil pressure.

That and amused comments from club members about the nice white smoke when downshifting convinced me of the necessity of a rebuild. And of course, since the engine comes out, why not rebuild the transmission?

|

|

1st time during dismantling |

|

|

2nd time for the full rebuild |

|

friends giving a hand |

Once apart, the engine showed wear consistent with mileage and probably marginal oil change frequency. One thing that surprised me was the verdict of the engine shop owner that I needed new piston. They looked a bit scuffed but measured quite OK to me. It seems that they have too wide a ring gap and they had to go.

All in all the engine ended up with the following work done and parts installed:

- New rocker shaft

- Rockers re-bushed

- New intake valves

- New valve guides

- New valve seats (I have to re-check on that)

- New valve springs

- Re-ground cam

- New cam bearing

- New tappets (i.e. cam followers)

- Re-ground crank (10 thousands undersize both main and rod journals)

- New main bearings

- New rod bearings

- Rebuilt oil pump (new gears)

- New timing chain

- New chain tensioner

- Lip seal conversion of the rear main bearing

- New seals and gaskets all around

- Block re-bored (20 thousands oversize)

- New AE brand Hepolite pistons (20 thousands oversize)

- Blueprinted, of course

Dismantling

Clean and shiny

Coming back from the shop all part were washed with brush and soap. After that, all dimensions were checked versus their nominal values as per BMC workshop manual and all measurements taken are logged in a separate logbook. The camshaft which is not pictured, was checked to bearing alignment, roundness and diameter. Cam angles were measured during the build (see below)

|

|

Build

Since I could not fit the block on my engine stand, engine was rebuilt on the shop floor with extreme care to cleanliness. Shop was constantly vacuumed (with vacuum cleaner outside the shop…) and plastic liner changed at every opportunity. Parts were cleaned and re-cleaned before mounting.

|

Dennis Welsh lipseal |

||

|

camshaft is checked |

|

Done!